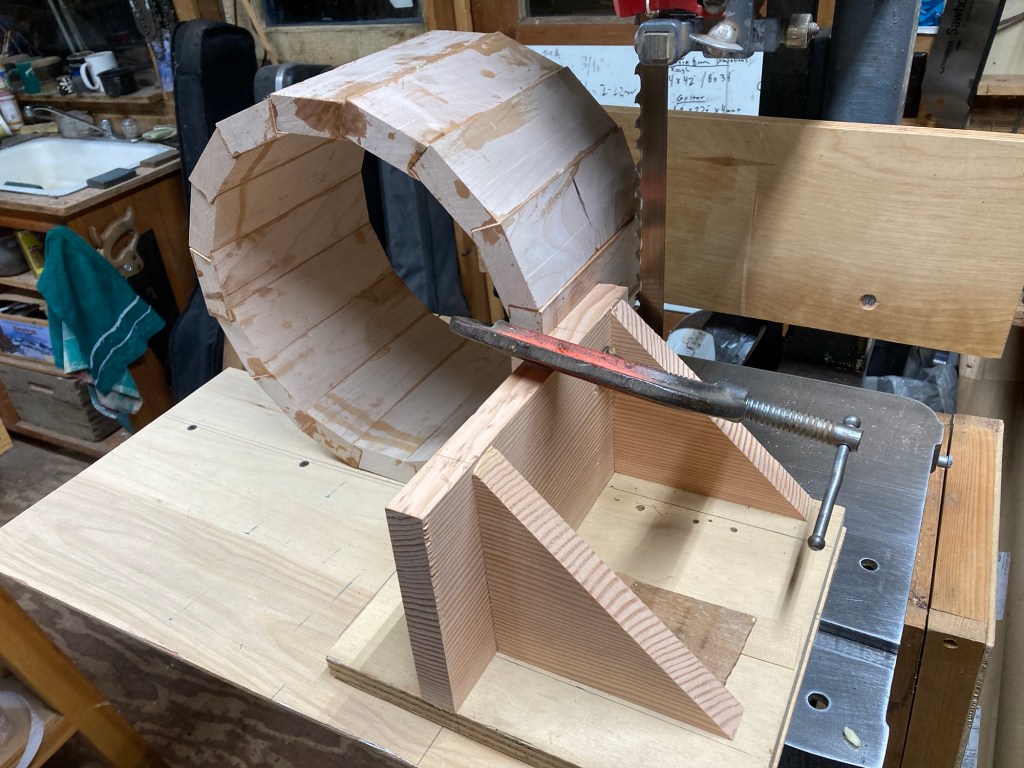

My bent lamination rims are still a work in progress (as with most everything I’m making) but I’ve put them on the back burner for now in favor of exploring the ‘stave’ method I’ve been working on. Someone on the Banjo Hangout forum mentioned it and it reminded me of when I made standup paddle board paddles using this method: http://sawdustfactory.nfshost.com/paddles/ which worked great and used eight staves.

This makes for a very strong structure, and relatively easy to put together, with the notches helping to hold it together while glueing. For the paddles I glued two at a time, then the four sets of two to manage it. Eight pieces, six feet long all at once before the glue set seemed too much for me. The paddles worked great (I did fiberglass them as well) until they burned in a forest fire in 2021.

I used a table saw to cut the notches for the paddles, a simple 45 degree v/cut. I wanted more staves for the banjo rims to have less flat surface to remove to get them to round. I opted for a router bit made for this purpose rather then fussing with the table saw. My rims use 16 staves, this is where I bought the bit: Woodline (no affiliation), there’s a few suppliers that carry these, probably most are equal in quality etc.

I like this method for a few reasons, it utilizes long grain glueing, it’s relatively easy to put together and clamp (note the cool band clamps) and once the glue is set it’s very strong. The banjo rims are easier to make then the paddle shafts, they’re straight sided, the paddles are tapered from end to end, not that difficult, but another step. I use epoxy to glue the staves together, very strong, doesn’t add moisture to the mix, and fills gaps. Titebond would work well too.

These are for 11″ rim banjos, I have a 14″ bandsaw with a riser block for resawing (12″ maximum cutting height), the rim & jig just fit under that limit, not sure what I’ll do if I make a 12″ rim. Works well, but definitely needs to be securely clamped to the jig. I did cut a rim on the tablesaw, using the fence as a guide, it worked but slightly stressful considering the potential for a mishap. The jig has a 1/4″ plywood base, so I put a scrap piece of the same under the barrel to keep it level while making the cut, as the blade wants to push the pot towards the saw table. It makes for a good 90 degree cut.

More to come..